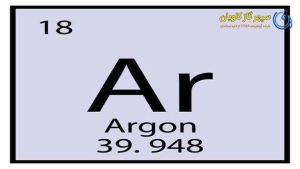

Argon gas

Argon gas is a colorless, odorless, and non-reactive gas that is the third most abundant gas in Earth’s atmosphere, making up about 0.93% of the air we breathe.

It is a noble gas, which means that it is chemically inert and does not react with other elements.

Sources

The primary source of this gas is the Earth’s atmosphere. This gas makes up about 0.94% of the atmosphere by volume, which is equivalent to about 1.288% by mass.

This gas is also present in trace amounts in Earth’s crust and seawater.

This gas is extracted from the atmosphere by cryogenic fractional distillation. This process involves cooling air to a very low temperature, at which point the different gases will liquefy at different temperatures.

This gas liquefies at 87.3 K, so it can be separated from other gases, such as nitrogen and oxygen, which liquefy at lower temperatures.

Here are some of the resources of this gas:

Air separation units are used to extract argon from the atmosphere. These units are typically located near large industrial centers, where there is a demand for argon.

Cryogenic plants are used to produce liquid argon. These plants are typically located in cold climates, where the cost of cooling the air is lower.

Argon cylinders are used to store and transport this gas. These cylinders are typically made of steel or aluminum and are filled with high-purity argon gas.

Sepher gas Kavian company produces all kinds of argon gas for quantum measurement devices, MRF, sells argon gas for welding protection, etc., has a valid certificate. Sepher gas kavian company, reference laboratory of the standard department, is active in the field of producing and importing argon gas for various industries and laboratory equipment and quantum measurement devices and gas mixtures (calibration gases) with high quality and all equipment related to various industries.

The volume of cylinders and capsules available for argon gas charging are: 5 liter cylinder, 10 liter cylinder, 20 liter cylinder, 40 liter cylinder, 50 liter cylinder with valves S3DIN6, B.

Production

The process of producing this gas from liquid air is as follows:

Air is compressed and cooled to a temperature of about -190 °C.

The cold air is then passed through a series of heat exchangers, which further cools the air to about -200 °C.

The cooled air is then passed through a distillation column, where the different gases are separated by their boiling points.

This gas is collected at the bottom of the distillation column.

The argon gas that is produced is typically about 99.9% pure. It can be further purified by passing it through a series of filters.

Here are some of the steps involved in the production of this gas:

Air separation. The first step is to separate the air into its component gases. This is done by compressing the air and cooling it to a very low temperature. The different gases will liquefy at different temperatures, so this allows them to be separated.

Fractional distillation. The next step is to use fractional distillation to separate the argon gas from the other gases.

This is a process of heating and cooling the liquid air, which causes the different gases to vaporize at different temperatures.

The argon vapor is then collected and condensed into liquid argon.

Purification. The final step is to purify the argon gas. This is done by passing the gas through a series of filters to remove impurities.

The production of this gas is a relatively simple process, but it requires specialized equipment and facilities.

The cost of producing argon gas is relatively low, which makes it an economical choice for a variety of applications.

Application of Argon gas

Here are some of the most common uses of this gas:

Welding and cutting this gas. is often used as a shielding gas in welding and cutting applications. It helps to prevent the oxidation of the metals being welded or cut, which can produce defects in the weld.

Glass blowing. This gas is used in glass blowing to prevent the oxidation of the glass. It also helps to create a clear, bubble-free finish.

Fluorescent lighting. This gas is used in fluorescent lighting to provide an inert atmosphere for the fluorescent lamp. This helps to prevent the lamp from blackening and extending its lifespan.

Cryogenics. This gas is used in cryogenics to cool materials to very low temperatures. This is used in a variety of applications, such as research, medical procedures, and food preservation.

Laboratory applications. This gas is used in a variety of laboratory applications, such as gas chromatography, mass spectrometry, and plasma etching.

Medical applications. This gas is used in medical applications, such as laser surgery and cryotherapy.

This gas is a safe and versatile gas with a wide range of uses. It is an important industrial gas and is used in a variety of applications.

Technical Specifications

| Molecular weight | 39.948 g/mol |

| Boiling point | -185.87°C / 87.28 K |

| Density | 1.691 kg/m3 (at 1.013 bar, 15°C) |

| Vapor pressure | 0.0132 bar (at 20°C) |

|

Flammability | Non-flammable |

| Toxicity |

Non-toxic |

DANGERS of Argon Gas

This gas a simple asphyxiant , which means that it displaces oxygen in the air and can cause suffocation. Symptoms of this gas poisoning include headache, rapid breathing, dizziness, confusion, tremors, loss of coordination and judgment, and lightheadedness. Higher levels can cause nausea, vomiting, unconsciousness, coma, and death.

There is no known antidote for this gas poisoning, so treatment is supportive. This means providing oxygen and treating the symptoms as they arise. In severe cases, this gas poisoning can be fatal.

To avoid this gas poisoning, it is important to work in a well-ventilated area and to wear a respirator if there is a risk of exposure to high concentrations of argon gas.